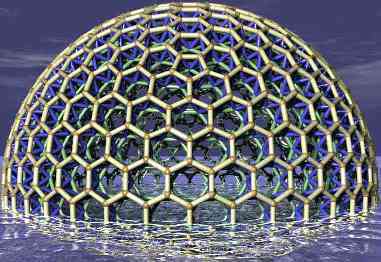

HexDome

Hexagonal Geodesic Domes - Honeycomb Domes

How to build a very big geodesic dome

How will our distant descendants build big geodesic domes?

This is my attempt to answer the questions surrounding the

issue of how best to build a very large geodesic dome.

Thickness

Very large domes necessarily have to be thicker than normal.

I decided to see how thick I could make a dome while

remaining subject to some constraints.

The main constraint I selected was that the weight-bearing

elements should be confined to one layer of the dome. The

other constraints were conventional ones - maximising

strength, minimising material and labour costs.

Here are some of the designs I came up with:

Attaching hexagonal layers together

One of the central technologies employed here is a method of

attaching two hexagonal layers together at right-angles.

As far as I can tell, this approach has not been employed by

previous designers. The following diagram illustrates the

attachment mechanism:

Attaching two hexagonal layers together

A conventional two-layer dome built using this technique

leaves something to be desired.

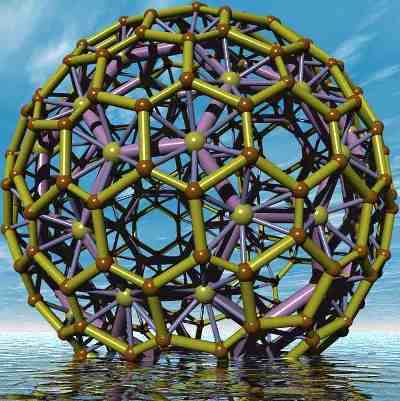

Three layers

To obtain the desired thickness (and strength) I investigated

constructions that placed reinforcing structural elements on

both sides of the main weight-bearing hexagonal layer.

The resulting designs all wound up having the main weight-

bearing elements surrounded on all sides by stabilising

components.

The approach resulted in a design looking like this:

Triple hexagonal layers

Hidden attractions

I find this design to be beautiful.

However, there are some pleasing aspects to this design that

may not be immediately obvious:

- One is that it resolves an issue afflicting two-layer dome

designs that makes in impractical to employ tension-only

components between the layers - since tightening them

results in stability issues.

The problem arises because the elements between the layers

(which it seems desirable to replace with cables) face no

opposition, and too easily fall together.

Having a third layer resolves this problem - the central

weight bearing layer is now being pulled in both

directions by the cables - and the forces balance.

The interior and exterior faces are connected together with

struts that keep them apart. Pulling them together fails

to make the two layers move together - because of these

struts.

- Another attraction is the relationship between the natural

strut lengths and their functions.

In domes like Fuller's Moscow dome and his Expo '67 dome,

the struts in the triangular layer are actually longer than

those in the hexagonal layer. The theory of hexagonal dome

design strongly suggests that the hexagonal layer should be

where the weight bearing components are concentrated if the

resulting dome is to be suitably light. However the combination

of long struts and light struts does not make structural sense -

struts that are long and light are struts that will

bend and break.

In domes like the ones illustrated here, the proper

relationship is restored: the strong hexagonal elements are

also the ones that are longest - and the weaker supporting

struts are all mercifully short.

- The technique of adding a smaller-mesh hexagonal layer

to an existing one breaks the relationship between strut

length and the size of the faces needed to cover the dome.

Having smaller regions that need covering by fabric should

mean that cheaper fabrics can be employed - and that

construction can be more modular. If necessary the

technique of adding finer layers could be iterated - further

reducing the structural demands placed on any covering

fabric.

Variations

I looked at some variations - to see if I could suck some

material out of the design - while still maintaining most

of its desirable traits.

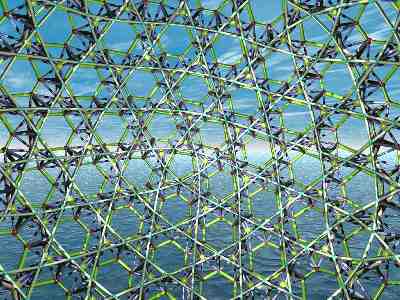

The first variation I considered involved replacing one

of the layers with a "triaxial weaving"-pattern layer.

Any of the three layers can be replaced in this way -

but it seemed to me that the most attractive one to target

was the interior layer.

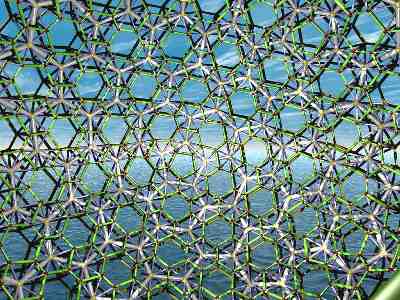

A snapshot of the resulting design (from inside):

Triaxial-weave and twin hexagonal layers - from inside

As well as eliminating some of the unnecessary struts, it

seems as though this operation converts many of the squares

in the original design into triangles - and thus may well

represent a substantial structural improvement.

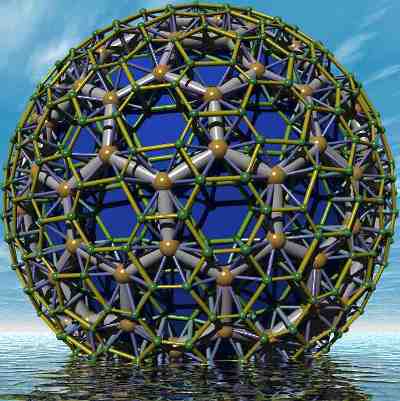

For the sake of comparison, here's the corresponding diagram

for a triple-hexagon dome:

Triple hexagonal layers - from inside

Using the triaxial weave internal layer does indeed appear

to save some nodes and struts while retaining most of the

design's desirable features - and without too many other

deleterious consequences.

The main other variations I considered were:

- Adding tensile-only elements into the dome's "windows";

- Attaching the centres of the main struts to the nearby nodes;

Making attachments to the middle of struts is often

considered to be taboo - but in the case of solid weight-

bearing struts - like those under consideration here - there

is no good reason to avoid doing it.

Tensegrity

As I've mentioned, one of the appealing aspects of this sort

of structure is that it makes using tension-only elements

to stabilise the structure relatively practical.

All the struts between the two exterior layers and

the main weight-bearing interior one could be replaced with

tensile-only elements.

There are two existing domes that illustrate the potential

of this approach - the ASM dome and the original

Climatron. I would classify both of these domes as

Honeycomb domes. Links to photographs of these

are available on this site's

links page.

Insulation

Multi-layer domes like these ones seem to beg for "double-

glazing". That would allow the environment containing the

struts to be controlled independently of the interior and

exterior space - and offer the best insulating layer.

The "triple-hexagon" structure - which presents both

interior and exterior fine-mesh hexagonal layers - seems

particularly well-suited to being insulated.

Disadvantages

The domes illustrated here are big and complicated - with

lots of nodes and struts - which cost money, need assembling

and maintaining - and block out the sky.

Clearly something along these lines is necessary for a

very large dome - but the question arises about at

what size a cheaper and simpler structure can be

employed.

This question will need some empirical work to answer

properly.

However, in my opinion - the answer to the question of at

what size such designs become appropriate is likely to be

"at a smaller scale than you might think".

These designs are extremely strong. Although they

have many elements, their structural strength means that

the elements that are used can be made lighter and cheaper

than would otherwise be possible.

That has positive effects on both construction costs and

material costs.

Gallery

If you are interested in seeing more of these Honeycomb dome, designs

then there are many more images of these in the

Honeycomb dome gallery.

Tim Tyler |

Contact |

http://hexdome.com/

|