Triaxial Weaving

Triaxial weaving

Triaxial weaving produces material which is structurally superior to most

sorts of rectangular weaving. Since the structural elements run in three

directions, the resulting fabric is much more resistant to shearing forces.

Here are the two most common types of triaxial weaving:

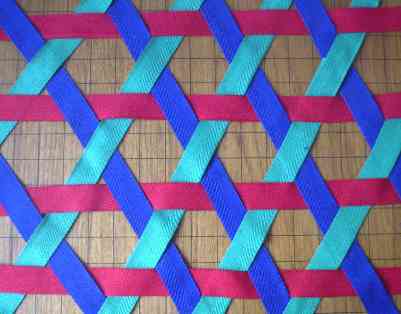

Dense triaxial weave

This fabric has three layers of material at any point - and

is thus stronger than a rectangular woven fabric made using

the same elements.

Unfortunately, this fabric is relatively difficult to

manufacture.

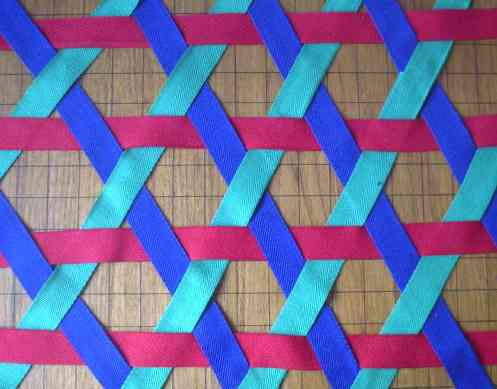

Sparse triaxial weave

This fabric is sparse. It

typically has about a third of

the structural elements of the first fabric.

One of the feature of this fabric that it has holes in it.

While this makes it unsuitable for some

applications, it does help with applications which

require ventilation - such as ladies stockings, linen

baskets or underwear.

Alternatively, it is appropriate where a light

material is required - that is still very strong.

As far as I know, this sort of weave is the lightest simple

weave known to man.

It also has the advantage of being pretty easy to

manufacture.

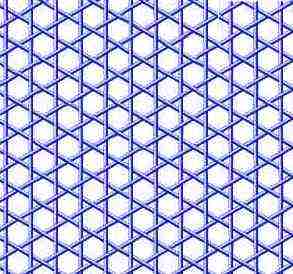

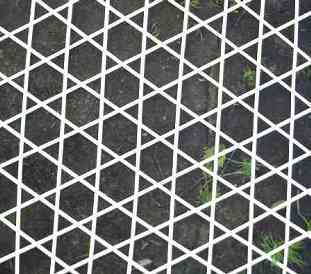

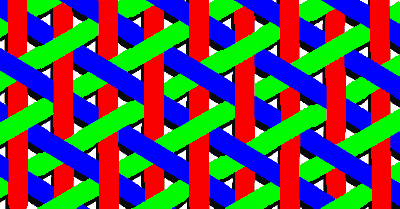

More diagrams

These diagrams show what sparse triaxial weaving looks like

on a larger scale:

Statistics

Some calculations relating to triaxial weaving:

| \ |

Density |

| Rectangular |

2.00 |

| Triaxial (sparse) |

1.00 |

| Triaxial (dense) |

3.00 |

| Diamond |

2.00 |

Ribbon-based model

| \ |

Density |

Sphere seive: cost |

Disc seive: cost |

| Rectangular |

2.00 |

2.00 |

2.82 |

| Triaxial (sparse) |

1.73 |

3.00 |

3.46 |

| Triaxial (dense) |

5.19 |

3.00 |

3.46 |

| Diamond |

2.31 |

2.00 |

4.00 |

| Hexagonal |

1.15 |

1.00 |

1.15 |

Wire-based model

The figures are derived from models based on "ribbon" or "wire".

The "ribbon" is considered to be a material which is very

wide in one dimension, while very narrow in another. The

"wire" is considered to be a very thin, but highly

inflexible material. In practice, most real materials will

fall somewhere between these extremes.

Sparse triaxial weaving using ribbons typically uses 50% of

the quantity of material to cover the same area as

rectangular rectangular weaving - while dense triaxial

weaving uses 150% of material to cover the same area.

If the material is ribbon-like the difference between

rectangular weaving and triaxial weaving is dramatic.

However - if the material is wire-like, there's not very

much in it.

The "seive" costs were intended to determine whether it

makes financial sense to build seives out of triaxial woven

fabrics. Two sorts of seive were considered - based on

whether the objects being seived were spheres or discs.

The figure represents the material cost (per unit area) to

prevent the passage of objects with diameter 1 unit.

The "Hexagonal" entry is not really a weave. It is

impossible to construct it using continuous strands. The

figures are given to allow comparisons with the ideal

arrangement.

In summary: even if you ignore the problems caused by the

variable-size pores; triaxial weaving probably makes little

sense in this application.

Applications

What applications are suitable for using triaxial techniques?

The main selling points of triaxial weaving are:

- Light weight;

- Low cost;

- Shear-resistance.

These are desirable traits for many applictations.

In particular, light shades, baskets and underwear seem

particularly attractive applications for this sort of

weaving.

Construction

Sparse triaxial weaving uses three sets of parallel fibres, known as the

warp, the whug and the weft.

The whug is not present in conventional rectangular weaving. During

construction it acts very much like a second warp.

The warp can be laid down in simple parallel lines. The whug is then

laid down on top of it - again in simple parallel lines.

Finally the weft is woven in and out of both layers - to create the final

fabric.

Patent

For many years triaxial fabrics were the subject of a patent:

See [here] for details.

This patent covers the "dense" form of triaxial weaving. It has now expired.

Medium triaxial weave

Medium triaxial weave

Here's a medium-density triaxial weaving pattern.

It is similar to the dense weave - but apparently not so symmetrical.

As with the other triaxial weaves, it should offer good shear resistance.

References

Tim Tyler |

Contact |

http://hexdome.com/

|